1 Yi shiri kafin taro

1.1Tabbatar cewa haɗin flange da aka zaɓa azaman ISO 6162-1 ya dace da buƙatun aikace-aikacen (misali matsa lamba, zazzabi da sauransu).

1.2Tabbatar cewa abubuwan haɗin flange (mai haɗa flange, manne, dunƙule, O-ring) da tashoshin jiragen ruwa sun dace da ISO 6162-1

1.3Tabbatar da madaidaitan sukurori, awo don nau'in 1 da inch don nau'in 2.

1.4Tabbatar cewa kar a haɗa abubuwan haɗin gwiwa tare da sassan ISO 6162-2.Yadda za a gane daban-daban ganiYadda za a gano ISO 6162-1 da ISO 6162-2 haɗin flange da abubuwan haɗin gwiwamahada.

1.5Tabbatar da cewa duk abin rufe fuska da musaya (haɗe da tashar jiragen ruwa da abubuwan flange) ba su da burrs, nick, scratches da kowane kayan waje.

2 Yadda ake taruwa daidai

2.1Don taimakawa rage gogewar O-ring, sa mai O-ring tare da gashin haske na ruwan hydraulic da ake amfani da shi a cikin tsarin ko mai mai jituwa, idan ya cancanta.Yi kulawa ta musamman, saboda yawan mai zai iya fita daga cikin haɗin gwiwa kuma ya haifar da alamar ƙarya na yabo.

Lura:Girman O-ring suna ganin tebur 1 ko tebur 2, kuma girmansa iri ɗaya ne don metric ko inch dunƙule, girman iri ɗaya ne don haɗin haɗin flange ISO 6162-1 da ISO 6162-2, babu batun gauraye.

2.2Sanya kan flanged da maƙallan flange.

2.3Sanya masu wanki masu tauri a kan sukurori, kuma sanya sukurori ta cikin ramukan da ke cikin matsi.

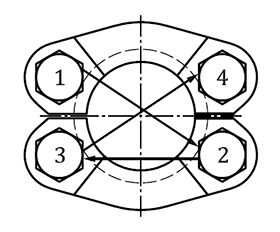

2.4Hannu yana ƙara matsar da sukurori a cikin jerin abubuwan da aka nuna a Hoto na 1 don tabbatar da tuntuɓar iri ɗaya a duk wuraren dunƙule huɗu don hana tipping ɗin flange, wanda zai iya haifar da fashewar flange yayin aikace-aikacen jujjuyawar ƙarshe.

Hoto 1 - Jumla tightening jerin

2.5Juya sukurori a cikin jeri da aka nuna a Hoto na 1 a cikin haɓaka biyu ko fiye zuwa matakin juzu'in da aka ba da shawarar da kuma amfani da madaidaitan ma'auni a cikin tebur 1 don ma'aunin ma'auni da tebur 2 don dunƙule inch.

TS EN ISO 6162-1 TS EN ISO 6162-1 Table 1

| Na suna girman | Matsakaicin aiki matsa lamba | Nau'in 1 (metric) | ||||||||

| Zaren dunƙulewa | Tsawon dunƙule mm | Juyawa juzu'i N.m | Wuta | O- zobe | ||||||

| MPa | bar | don hexagon dunƙule kai mm | don soket dunƙule kai mm | Code | Inside diamita mm | Cross - sashe mm | ||||

| 13 | 35 | 350 | M8 | 25 | 32 | 13 | 6 | 210 | 18.64 | 3.53 |

| 19 | 35 | 350 | M10 | 30 | 70 | 16 | 8 | 214 | 24.99 | 3.53 |

| 25 | 32 | 320 | M10 | 30 | 70 | 16 | 8 | 219 | 32.92 | 3.53 |

| 32 | 28 | 280 | M10 | 30 | 70 | 16 | 8 | 222 | 37.69 | 3.53 |

| 38 | 21 | 210 | M12 | 35 | 130 | 18 | 10 | 225 | 47.22 | 3.53 |

| 51 | 21 | 210 | M12 | 35 | 130 | 18 | 10 | 228 | 56.74 | 3.53 |

| 64 | 17.5 | 175 | M12 | 40 | 130 | 18 | 10 | 232 | 69.44 | 3.53 |

| 76 | 16 | 160 | M16 | 50 | 295 | 24 | 14 | 237 | 85.32 | 3.53 |

| 89 | 3.5 | 35 | M16 | 50 | 295 | 24 | 14 | 241 | 98.02 | 3.53 |

| 102 | 3.5 | 35 | M16 | 50 | 295 | 24 | 14 | 245 | 110.72 | 3.53 |

| 127 | 3.5 | 35 | M16 | 55 | 295 | 24 | 14 | 253 | 136.12 | 3.53 |

TS EN ISO 6162-2 Tebur 2 - Girman karfin juyi da wrench tare da dunƙule inch don haɗa haɗin flange waɗanda suka dace da TS EN ISO 6162-1

| Na suna girman | Matsakaicin aiki matsa lamba | Nau'in 2 (inch) | ||||||||

| Zaren dunƙulewa | Tsawon dunƙule mm | Juyawa juzu'i N.m | Wuta | O- zobe | ||||||

| MPa | bar | don hexagon dunƙule kai in | don soket dunƙule kai in | Code | Inside diamita mm | Cross - sashe mm | ||||

| 13 | 35 | 350 | 5/16-18 | 32 | 32 | 1/2 | 1/4 | 210 | 18.64 | 3.53 |

| 19 | 35 | 350 | 3/8-16 | 32 | 60 | 9/16 | 5/16 | 214 | 24.99 | 3.53 |

| 25 | 32 | 320 | 3/8-16 | 32 | 60 | 9/16 | 5/16 | 219 | 32.92 | 3.53 |

| 32 | 28 | 280 | 7/16-14 | 38 | 92 | 5/8 | 3/8 | 222 | 37.69 | 3.53 |

| 38 | 21 | 210 | 1/2-13 | 38 | 150 | 3/4 | 3/8 | 225 | 47.22 | 3.53 |

| 51 | 21 | 210 | 1/2-13 | 38 | 150 | 3/4 | 3/8 | 228 | 56.74 | 3.53 |

| 64 | 17.5 | 175 | 1/2-13 | 44 | 150 | 3/4 | 3/8 | 232 | 69.44 | 3.53 |

| 76 | 16 | 160 | 5/8-11 | 44 | 295 | 15/16 | 1/2 | 237 | 85.32 | 3.53 |

| 89 | 3.5 | 35 | 5/8-11 | 51 | 295 | 15/16 | 1/2 | 241 | 98.02 | 3.53 |

| 102 | 3.5 | 35 | 5/8-11 | 51 | 295 | 15/16 | 1/2 | 245 | 110.72 | 3.53 |

| 127 | 3.5 | 35 | 5/8-11 | 57 | 295 | 15/16 | 1/2 | 253 | 136.12 | 3.53 |

Lokacin aikawa: Janairu-20-2022